left window is as always, right window has interior storm window installed

maine houses are typically poorly built, poorly insulated, and old. this translates to drafty as fuck with the heat retaining value of a cardboard box. maine is also a state of "cottage industries", or people building useful shit out of their homes for fun and profit. several communities have neighborhood build days, where you volunteer your time to build interior storm windows for your house, and then help with a less fortunate neighbor's build. several companies will also do the work for you, and you just pay them standard cost of materials/labor/profit. i was willing to do this..until i called and they are all booked through spring. the midcoast green collaborative, island institute, and art tec all offer online instructions on how to diy your storm windows, so off to the home depot i drove.

generally, the depot doesnt sell insulating kits unless it's winter, and i figured frank-the-devil-cat will put his claws through atleast one or 7 of the storm windows; i bought extras of everything. here's what one window will cost [most of the instructions and pdfs i found did cost per inch/foot/square foot]:

- shrink wrap and tape: $3.11

- foam tape: $5.97

- tape: $3.74

- screws: $.74

- 1"x2"x8': $11.64

all the instructions i found sum up to this: build frame slightly smaller than window opening, attach 2 layers of shrink wrap, tape edges, add foam tape, shove into window. good in general, but more than a few steps were rather confusing. i don't purport to write the clearest directions, but jeebus. here's my attempt.

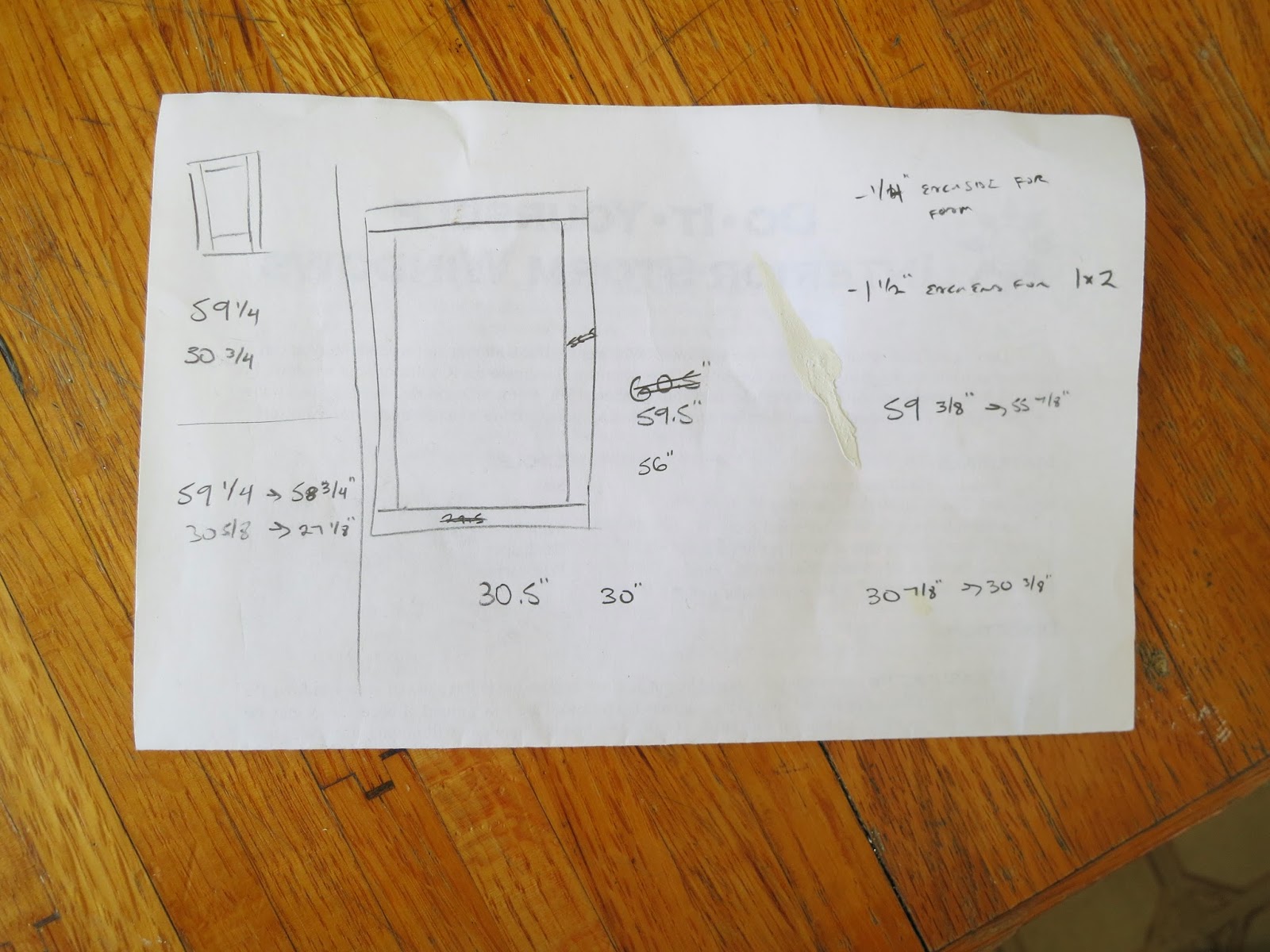

measure window. write down dimensions to the nearest 1/8th inch. then measure the window again. theeeen just for good measure [hahh..] do it again. verify you are getting the same number you have written down.

now it's time for math. *cue dramatic music*

first determine if you are going to have the top overlap the sides, or the sides overlap the top. i drew both as i ... might have screwed one up and had some too short pieces leftover. but the first one has exterior dimensions of 59.5"x30.5". i determined the foam tape would compress to about 1/4", and the 1"x2"s i had were actually 1 1/2" wide after milling. that means... subtraction. i needed the top bars to be 30" long and the sides to be 56". easy enough. just write everything down. since i apparently have a goldfish memory, this piece of paper went all over the house with me. and ended up with paint on it somehow.

once you have your top, bottom, and sides cut, align them and drill a pilot hole. since i didn't have a fancy pants corner clamp, i drilled the outermost hole through both pieces and then redrilled the side a bit deeper. then i put the screw in, and drilled a second pilot hole. don't try to align both holes and deepen them in the sides. unless you have octopus arms. there just arent enough hands to hold all the things.

once you have all 4 sides together, bust out that paint. or not. but you only have to do the front [outer face] and the 4 inner sides. the back [unless you have crazy neighbors] and outer sides will never be seen. if you even have the slightest inkling you want to paint the frame, do it. once the plastic is on... you cant. let dry. forrreeeevvveerrrrr. bonus points if you get the reference.

i used my homemade chalk paint leftovers from my dresser redo. weeeeell its plaster in paint. you can imagine how well it kept over the past 10 months.. looots of stirring, some shaking, and attempts to not dislodge the solid goop at the bottom resulted in relative success. nice matte frames with a minimum of lumps.

now... put double sided tape around the edge. atleast that's what all the instructions i had said. and i pondered this for a bit and realized.. they meant the outer edge of the front [and back] faces. not the actual outside edge. put all your tape on the front side first [so you dont flip it over and scratch the paint]. then align a sheet of shrink wrap and start sticking that crap down. now again, most of the instructions i found said to trim the excess to within a 1/2" or so, and shrink it.

instead, flip the frame over and repeat the taping and sticking process on the backside. then trim the edges close, and use super-heavy-duty-long-lasting-high-quality-weather-proof-over-priced tape. the internets told me to fold nice neat corners. i disagree. instead, from the painted side, overlay the tape so you will end up with just a small fold onto the back side. about a 1/3rd of the width of the tape will be on the front, another 1/2 is along the outside edge, and the last 1/6th is on the back. press all the tape down firmly, and avoid creases and air bubbles wherever possible. flip the whole frame over and tape on the back side so 2/3rds of the tape is aligned on the back, with the remaining 1/3rd on the outside edge with none on the front. cut the tape so it is about 1/8" shy of the corners. now with all edges nicely neatly and doubley reinforced, bust out the hair dryer and shrink that shit. just dont melt anything. in all my years of sealing off windows during winters in long island, i didnt manage to melt the plastic. and i had many chances each season. curious kitty does not like to be sealed out of window ledges.

but really. look how friggin nice and shiny that looks! tape is barely visible around the edges, and the screws will be covered shortly. make sure you add a tab for easy removal. veeeery necessary. top, or bottom, just make sure that shit is secured.

then for the true test of your measuring skills: cram the frame into the window. there should be a 1/4" gap around each side, which equates to about room to smoosh a fingertip into.

add the foam tape around the edges, and again, cram that bad boy in place. i ended up removing the foam tape along the top of this frame since i only measured.. twice. also, the foam tape i have apparently doesnt compress quite as much as expected. the storm window is only slightly hazy compared to the dirty dirty glass behind it, and as i was man-handling it in place, i could feel around the edges where cold air was leaking out. pretty impressive what just two layers of plastic can block.

here's a close up of the living room window with the storm insert already in. the frame is the same color as my walls [..white. shocker i know.] and it matches with the old vinyl windows pretty well. i debated a bit as to whether the storm windows should match the actual frame, dark chocolate brown, or just be white like the existing frames. i went with white, and as the very top picture shows, theyre pretty indistinguishable.

so there you have it. probably the longest most verbose post ive ever written, with a lot of overly detailed pictures and explanations. go. build things. save yourself some heating costs.

I believe that interior storm windows are important in every homes.

ReplyDeleteThx. This is ��

ReplyDelete